In the rapidly evolving world of manufacturing, prototype injection molding stands at the forefront of innovation. This crucial process, employed to create preliminary models of products, has traditionally been a time-consuming and costly endeavor. However, recent advancements in technology are transforming Prototype Injection Molding, making it faster, more efficient, and cost-effective. These changes are enabling manufacturers to accelerate product development and stay ahead in competitive markets.

Breakthrough Technologies Enhancing Efficiency

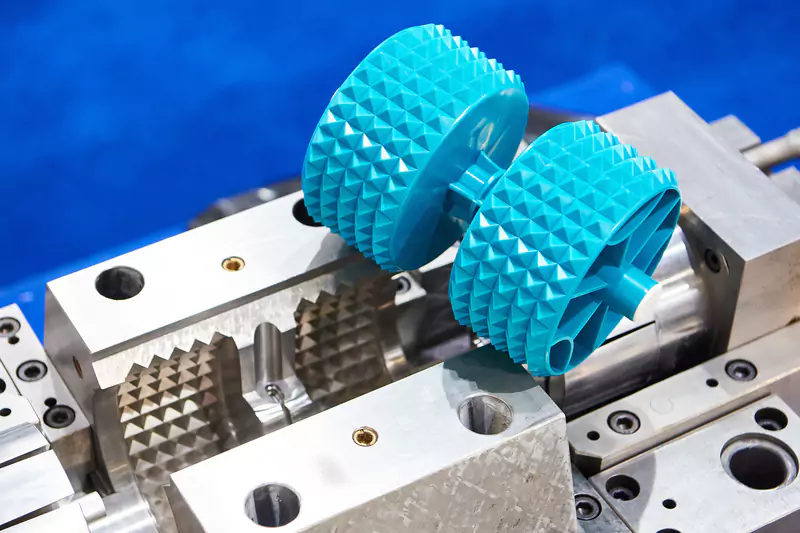

One of the most significant advancements in prototype injection molding is the development of high-speed, precision-controlled machines. These machines use sophisticated algorithms and real-time monitoring to ensure accuracy and consistency in the molding process. By reducing cycle times and minimizing material waste, manufacturers can produce prototypes more quickly and affordably.

Additionally, the integration of additive manufacturing technologies, such as 3D printing, with traditional injection molding techniques has revolutionized the industry. Hybrid systems that combine these technologies allow for rapid production of complex geometries and intricate designs. This synergy not only speeds up the prototyping phase but also provides designers with greater flexibility and creative freedom.

Material Innovations Driving Progress

The evolution of materials used in prototype injection molding is another key factor driving innovation. Advances in polymer science have led to the development of new, high-performance materials that offer superior mechanical properties, enhanced durability, and greater thermal resistance. These materials enable the creation of prototypes that closely mimic the final product’s performance characteristics, providing more accurate testing and validation.

Furthermore, the use of specialized additives and composite materials has opened up new possibilities for customizing prototypes. Manufacturers can now tailor the properties of their prototypes to meet specific requirements, such as increased strength or improved resistance to environmental factors. This level of customization enhances the accuracy of prototype testing and helps in identifying potential issues before full-scale production.

Cost Reduction through Technological Integration

One of the most compelling benefits of advanced prototype injection molding methods is the reduction in costs. Traditional molding processes often involve significant upfront investments in tooling and setup, which can be prohibitive for smaller companies or startups. Modern techniques, such as digital molding and modular tooling systems, have dramatically lowered these costs by streamlining the production process and reducing the need for extensive tooling changes.

Additionally, the use of simulation software has become increasingly prevalent in prototype injection molding. These tools allow engineers to predict and analyze the behavior of materials and the molding process before physical production begins. By identifying potential issues and optimizing designs virtually, companies can minimize costly revisions and rework during the physical prototyping phase.

Future Outlook and Industry Impact

As prototype injection molding continues to evolve, its impact on various industries is becoming more pronounced. The automotive, aerospace, and consumer goods sectors, in particular, are benefiting from these advancements, as faster prototyping translates into shorter development cycles and quicker time-to-market. The ability to iterate rapidly and test multiple design variations also fosters innovation and accelerates the introduction of new products.

Looking ahead, the integration of artificial intelligence and machine learning into prototype injection molding processes promises even greater advancements. These technologies have the potential to further enhance precision, optimize material usage, and streamline production workflows, driving the next wave of innovation in the industry.