In the modern age of manufacturing, few technologies have had as profound an impact as Computer Numerical Control (CNC) machining. This sophisticated process, often described as a blend of science and art, has revolutionized how we transform raw materials into precision-engineered components. From aerospace to medical devices, CNC machining is the backbone of industries that require impeccable accuracy. But what exactly is CNC machining, and how does it elevate raw materials into works of precision art?

Understanding CNC Machining

CNC machining is a process where computer-controlled machines precisely cut, shape, and finish materials into intricate designs. Unlike manual machining, where a human operator controls the machine, CNC machining relies on a computer program that dictates every movement. This allows for unparalleled accuracy, consistency, and repeatability, making it possible to produce complex parts with exacting tolerances.

The process begins with a digital design, typically created using Computer-Aided Design (CAD) software. This design is then converted into a CNC program, which the machine follows to produce the desired part. The machine, guided by the program, removes material from a block, or billet, of raw material through various methods such as milling, turning, or drilling. The result is a part that perfectly matches the digital design, with no room for error.

The Art of Material Selection

The first step in CNC machining’s transformative process is selecting the right material. The choice of material is critical, as it influences the part’s performance, durability, and manufacturability. Engineers and designers consider factors such as strength, weight, corrosion resistance, and thermal properties when choosing a material.

Common materials used in CNC Machining include metals like aluminum, steel, and titanium, as well as plastics like ABS, polycarbonate, and nylon. Each material has its own set of characteristics that make it suitable for specific applications. For example, aluminum is lightweight and easy to machine, making it ideal for aerospace components. On the other hand, titanium is highly durable and resistant to corrosion, making it perfect for medical implants.

Precision Engineering The Heart of CNC Machining

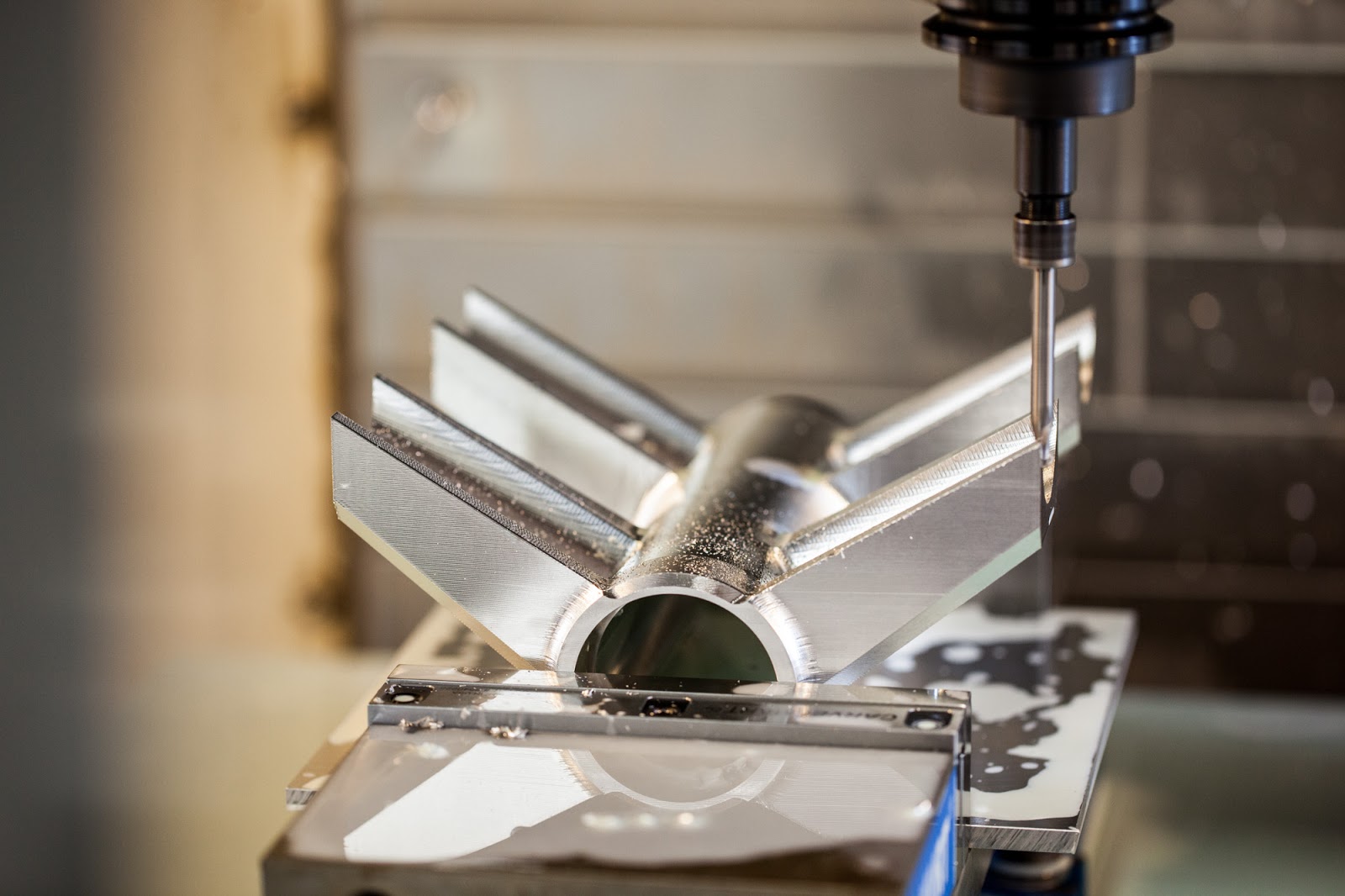

Once the material is selected, the magic of CNC machining truly begins. The machine, armed with its program, cuts away excess material to reveal the final shape. This process requires extreme precision, often down to microns (one-thousandth of a millimeter).

CNC machines are equipped with advanced tools like high-speed spindles, precision cutters, and multiple axes of movement, allowing them to create parts with intricate geometries and tight tolerances. This level of precision is crucial for industries where even the smallest deviation can lead to failure, such as in aerospace or medical devices.

The Human Touch Finishing and Quality Control

While CNC machines handle the bulk of the work, the human touch is still essential in the final stages of production. After machining, parts often undergo finishing processes like polishing, anodizing, or painting to achieve the desired surface finish and appearance.

Quality control is another critical step, where skilled technicians use precision measuring tools to ensure each part meets the required specifications. This blend of machine precision and human expertise is what elevates CNC machining from mere manufacturing to an art form.